Abstract: Choosing the right floating seal doubles the efficiency of tunnel boring machines and drilling rigs. In this article, we briefly discuss the principles of hobbing cutter lifespan, and in the next article, we will focus on how to choose the floating seal for tunnel boring machines.

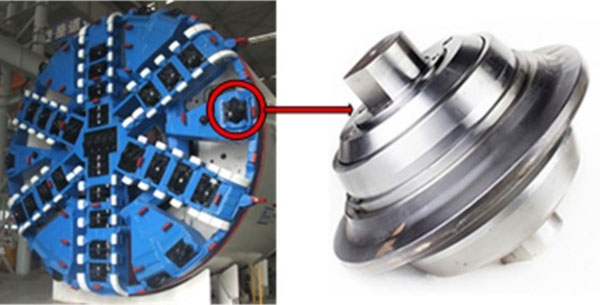

Shield machines and drilling rigs operate in muddy slurries, making the loading and unloading of hobbing cutters very difficult during the drilling process. Therefore, extending the lifespan of hobbing cutters is crucial to improve tunnel drilling efficiency. The lifespan of hobbing cutters depends on its material, structure, bearings, and floating seal components. The hobbing cutters can only successfully drill into rock when its contact pressure exceeds the rock's uniaxial compressive strength. The smooth operation of the hobbing cutters relies on the performance of bearings and floating seal components.

The hobbing cutter bearings are used to transmit the drilling pressure and maintain the rotation of the boring machine’s hobbing cutter body. For the service life of the bearings, the floating seal is a critical factor. In addition, when the floating seal is not well sealed, the pressure inside and outside the hobbing cutter becomes unbalanced, making it very easy for mud and slurry to be squeezed into the interior. This causes bearing wear and uneven wear of the cutter, leading to the cutter being quickly scrapped.

Therefore, the quality of the floating seal used internally in the cutter, the precautions during installation, and whether the floating seal has self-adjustability to external pressure will directly determine the service life of the cutter.

Fuyote established in 1992, has been 30 years in china. Focus on floating seals design and manufacture. In the past two decades, large size floating seals are the main products in fuyote’s production line. Diameter from 300mm to 1105mm are the best-selling products in fuyote. In order to guarantee high quality of the products, Fuyote manufactures all components of mechanical face seals in house, from casting metal rings with high chromium molybdenum to manufacturing elastomer components.