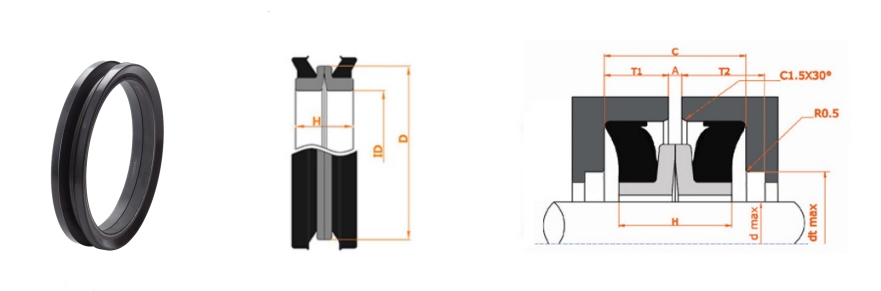

DF Heavy Duty Seals, also known as DF floating seals, are specialized mechanical seals designed for robust performance in heavy-duty applications. They are constructed with two rectangular rubber rings and a metal ring. The metal ring features an L-shaped contact surface with the rubber rings. This unique design allows the seals to create a dynamic sealing system that effectively prevents fluid leakage and protects against contaminants in demanding environments.

The operation of DF Heavy Duty Seals is stabilized by the transmission force generated from the torque of the rubber rings. This force ensures that the floating seals maintain their position and effectiveness within their seat cavity during operation. These seals are commonly used in various heavy machinery applications, including construction equipment, mining machinery, agricultural machinery, and industrial gearboxes, where reliable sealing and protection are crucial for equipment performance and longevity.

Available heavy-duty seal sizes from Fuyote:

· Outer Diameter: 59~800mm

· Inner Diameter: 42~750mm

· Thickness: 14~54mm

Metal Seal Ring Materials: Fuyote's DF heavy-duty metal seal rings are manufactured of high alloy cast iron. We offer two kinds of material for seal rings: Chromiun Molybdenum Alloy and High Chromiun Molybdenum Alloy.

O-ring Materials: The material of elastomer components determines their tolerance for temperature and pressure. Fuyote provides three types of materials for o-rings: NBR, HNBR, and Silicone.

Advantages of heavy-duty seals: easy-to-process housing bores and highly sealing reliability.

Primary Applications of DF heavy duty seals: off-road and tracked vehicles, conveyors, construction equipment, agricultural machinery, and mining equipment.

| Drawing No. | Seal Set | Shaft (Max) | Housing Bore | |||||||

| PN# | A= | D | ID | H | d | Bore depth | Recommended shoulder dia | Bore depth | T2 | C |

| de | dt | T1 | ||||||||

| CS0420DF | 59.0 | 42.0 | 20.0 | 39.0 | 65.0 | 53.0 | 10.0 | 10.5 | 23.0 | |

| CS0470DF | 62.0 | 47.0 | 20.0 | 44.0 | 70.0 | 58.0 | 11.5 | 11.5 | 23.0 | |

| CS0450DF | 65.0 | 45.0 | 22.0 | 42.0 | 70.1 | 58.0 | 11.5 | 12.1 | 24.7 | |

| CS0505DF | 65.0 | 50.5 | 19.0 | 46.5 | 76.2 | 63.0 | 10.5 | 11.0 | 23.0 | |

| CS0540DF | 73.0 | 54.0 | 22.0 | 50.0 | 80.0 | 67.0 | 11.5 | 12.0 | 26.0 | |

| CS0585DF | 73.0 | 58.5 | 19.0 | 54.0 | 82.6 | 65.0 | 10.0 | 11.0 | 23.0 | |

| CS0586DF | 80.0 | 58.6 | 19.6 | 54.0 | 84.0 | 71.0 | 9.0 | 9.5 | 21.0 | |

| CS0600DF | 80.0 | 60.0 | 24.0 | 56.0 | 85.0 | 70.0 | 10.5 | 10.5 | 28.0 | |

| CS0635DF | 81.0 | 63.5 | 19.0 | 59.5 | 87.8 | 71.0 | 9.0 | 9.5 | 21.0 | |

| CS0670DF | 86.2 | 67.0 | 20.0 | 64.0 | 95.5 | 82.0 | 10.0 | 11.0 | 23.0 | |

| CS0671DF | 91.7 | 67.0 | 20.0 | 64.0 | 95.5 | 82.0 | 10.0 | 11.0 | 23.0 | |

| CS0740DF | 92.8 | 73.8 | 20.0 | 70.0 | 102.2 | 88.0 | 10.0 | 11.0 | 23.0 | |

| CS0741DF | 99.0 | 74.0 | 20.0 | 70.0 | 102.2 | 88.0 | 10.0 | 11.0 | 23.0 | |

| CS0760DF | 90.0 | 76.0 | 17.0 | 73.0 | 95.0 | 83.0 | 8.0 | 9.5 | 18.0 | |

| CS0770DF | 97.0 | 77.0 | 25.0 | 74.0 | 105.0 | 87.0 | 12.5 | 13.5 | 29.0 | |

| CS0820DF | 101.5 | 82.0 | 20.0 | 78.0 | 110.2 | 96.0 | 10.0 | 11.0 | 23.0 | |

| CS0825DF | 100.0 | 82.5 | 22.0 | 78.0 | 114.3 | 97.0 | 11.0 | 12.0 | 25.5 | |

| CS0875DF | 111.5 | 87.5 | 19.0 | 85.0 | 115.8 | 102.0 | 10.0 | 11.0 | 23.0 | |

| CS0880DF | 104.0 | 88.0 | 19.0 | 85.5 | 113.0 | 98.0 | 8.0 | 9.5 | 20.0 | |

| CS0920DF | 113.0 | 92.0 | 24.0 | 88.0 | 125.8 | 109.0 | 12.5 | 13.0 | 28.0 | |

| CS0940DF | 115.0 | 94.0 | 24.0 | 90.0 | 125.8 | 109.0 | 12.5 | 13.0 | 28.0 | |

| CS0941DF | 120.0 | 94.0 | 24.0 | 90.0 | 125.8 | 109.0 | 12.5 | 13.0 | 28.0 | |

| CS0990DF | 123.0 | 99.0 | 19.0 | 95.0 | 127.3 | 113.0 | 10.0 | 11.0 | 23.0 | |

| CS0991DF | 120.0 | 99.0 | 17.5 | 95.0 | 124.0 | 110.0 | 8.5 | 9.5 | 20.0 | |

| CS1040DF | 132.0 | 104.0 | 27.0 | 100.0 | 141.2 | 121.0 | 15.0 | 16.0 | 32.2 | |

| CS1050DF | 124.0 | 105.0 | 24.0 | 100.0 | 135.0 | 114.0 | 12.0 | 13.0 | 28.0 | |

| CS1140DF | 133.2 | 114.0 | 26.0 | 110.0 | 148.0 | 130.0 | 12.0 | 13.0 | 28.0 | |

| CS1141DF | 138.0 | 114.0 | 26.0 | 110.0 | 148.0 | 126.0 | 12.0 | 13.0 | 28.0 | |

| CS1150DF | 141.0 | 115.0 | 28.0 | 112.0 | 152.4 | 131.4 | 15.3 | 15.3 | 33.6 | |

| CS1240DF | 144.0 | 124.0 | 32.0 | 120.0 | 162.5 | 142.0 | 18.3 | 20.0 | 39.6 | |

| CS1330DF | 156.0 | 133.0 | 28.0 | 128.0 | 171.5 | 151.0 | 15.3 | 15.3 | 32.6 | |

| CS1340DF | 155.6 | 134.0 | 22.0 | 130.0 | 162.6 | 152.0 | 10.7 | 13.1 | 22.8 | |

| CS1425DF | 161.0 | 142.5 | 24.0 | 138.0 | 173.0 | 139.7 | 11.1 | 11.1 | 27.7 | |

| CS1430DF | 165.0 | 143.0 | 28.0 | 139.0 | 177.5 | 168.0 | 15.8 | 16.8 | 33.6 | |

| CS1431DF | 166.0 | 143.0 | 28.0 | 139.7 | 174.0 | 158.8 | 15.5 | 15.5 | 33.0 | |

| CS1480DF | 172.0 | 148.0 | 29.0 | 144.0 | 184.5 | 164.7 | 16.5 | 16.5 | 35.0 | |

| CS1485DF | 167.9 | 148.5 | 28.0 | 143.0 | 184.1 | 164.0 | 16.5 | 18.0 | 35.0 | |

| CS1481DF | 168.0 | 148.5 | 32.4 | 143.0 | 188.9 | 172.0 | 16.5 | 16.5 | 36.0 | |

| CS1500DF | 175.0 | 150.0 | 30.0 | 145.0 | 190.0 | 170.0 | 16.5 | 18.0 | 35.0 | |

| CS1501DF | 177.0 | 150.0 | 32.0 | 145.0 | 184.1 | 164.0 | 16.5 | 18.0 | 35.0 | |

| CS1520DF | 178.0 | 152.0 | 32.0 | 149.0 | 192.0 | 172.0 | 14.0 | 16.5 | 31.0 | |

| CS1540DF | 180.0 | 154.0 | 36.0 | 149.0 | 194.0 | 174.0 | 18.4 | 18.4 | 38.5 | |

| CS1541DF | 180.4 | 154.0 | 30.0 | 149.0 | 190.0 | 170.0 | 16.0 | 18.0 | 35.0 | |

| CS1580DF | 180.0 | 158.0 | 18.0 | 153.0 | 190.0 | 174.0 | 8.0 | 10.0 | 22.0 | |

| CS1600DF | 180.0 | 160.0 | 36.0 | 155.0 | 194.0 | 174.0 | 18.4 | 18.4 | 38.5 | |

| CS1630DF | 184.0 | 163.0 | 30.0 | 158.0 | 190.5 | 175.0 | 15.0 | 15.0 | 31.8 | |

| CS1690DF | 195.0 | 169.0 | 33.0 | 164.0 | 206.2 | 191.5 | 15.1 | 18.4 | 32.2 | |

| CS1740DF | 194.0 | 174.0 | 23.0 | 170.0 | 204.7 | 190.5 | 10.7 | 13.1 | 22.8 | |

| CS1780DF | 207.0 | 178.0 | 29.0 | 174.0 | 218.9 | 197.0 | 16.5 | 16.5 | 35.0 | |

| CS1920DF | 218.0 | 192.0 | 32.0 | 187.0 | 231.0 | 206.0 | 15.2 | 17.0 | 32.4 | |

| CS1930DF | 214.3 | 193.0 | 32.0 | 188.0 | 238.7 | 215.0 | 20.1 | 20.1 | 42.2 | |

| CS1931DF | 223.0 | 193.0 | 32.0 | 188.0 | 238.7 | 215.0 | 20.1 | 20.1 | 42.2 | |

| CS1980DF | 224.0 | 198.0 | 35.0 | 195.0 | 245.0 | 223.0 | 17.0 | 17.0 | 40.0 | |

| CS1981DF | 220.0 | 198.0 | 18.0 | 195.0 | 228.6 | 212.0 | 10.5 | 12.0 | 23.0 | |

| CS2030DF | 229.5 | 203.0 | 38.0 | 198.0 | 254.0 | 235.0 | 21.2 | 23.0 | 44.5 | |

| CS2060DF | 237.5 | 206.0 | 38.0 | 202.0 | 254.0 | 235.0 | 21.2 | 23.0 | 44.5 | |

| CS2135DF | 238.0 | 213.5 | 28.0 | 209.0 | 254.0 | 240.0 | 13.7 | 15.2 | 32.0 | |

| CS2140DF | 242.0 | 215.0 | 38.0 | 210.0 | 255.5 | 235.0 | 18.9 | 21.2 | 39.6 | |

| CS2150DF | 249.0 | 215.0 | 38.0 | 210.0 | 255.5 | 235.0 | 18.90 | 21.20 | 39.6 | |

| CS2220DF | 244.6 | 222.0 | 22.0 | 217.0 | 254.0 | 240.0 | 10.5 | 10.5 | 23.0 | |

| CS2250DF | 246.0 | 225.0 | 40.0 | 221.0 | 277.1 | 247.0 | 23.7 | 23.7 | 49.0 | |

| CS2251DF | 246.0 | 225.0 | 36.0 | 221.0 | 266.8 | 247.0 | 18.2 | 18.2 | 38.1 | |

| CS2260DF | 256.0 | 226.0 | 40.0 | 220.0 | 277.1 | 247.0 | 23.7 | 23.7 | 49.0 | |

| CS2280DF | 260.5 | 228.0 | 40.0 | 221.0 | 277.1 | 247.5 | 23.7 | 23.7 | 49.0 | |

| CS2330DF | 259.0 | 233.0 | 35.0 | 225.0 | 280.0 | 250.0 | 17.0 | 18.0 | 40.0 | |

| CS2360DF | 265.0 | 236.0 | 30.0 | 231.0 | 273.1 | 230.0 | 15.6 | 17.0 | 34.2 | |

| CS2380DF | 261.9 | 238.0 | 22.0 | 233.0 | 269.9 | 255.0 | 10.7 | 10.7 | 22.9 | |

| CS2390DF | 264.0 | 239.0 | 36.0 | 234.0 | 279.4 | 261.9 | 17.5 | 20.0 | 36.5 | |

| CS2410DF | 261.3 | 241.0 | 22.0 | 236.0 | 269.9 | 255.0 | 10.6 | 10.6 | 22.2 | |

| CS2415DF | 273.5 | 241.5 | 36.0 | 236.0 | 279.4 | 260.6 | 17.5 | 20.0 | 36.5 | |

| CS2416DF | 273.5 | 241.6 | 36.0 | 236.0 | 295.3 | 273.0 | 21.3 | 21.3 | 44.6 | |

| CS2470DF | 270.5 | 247.0 | 41.0 | 243.0 | 301.2 | 272.0 | 23.5 | 23.5 | 49.5 | |

| CS2485DF | 269.1 | 248.5 | 28.0 | 243.0 | 279.4 | 260.0 | 12.7 | 12.7 | 28.9 | |

| CS2520DF | 282.0 | 252.0 | 38.0 | 248.0 | 295.2 | 272.0 | 20.7 | 23.0 | 44.5 | |

| CS2580DF | 286.0 | 258.0 | 28.0 | 253.0 | 292.1 | 276.0 | 15.6 | 17.0 | 33.2 | |

| CS2750DF | 303.0 | 275.0 | 36.0 | 270.0 | 309.4 | 290.0 | 17.5 | 20.0 | 37.0 | |

| CS2830DF | 305.0 | 283.0 | 42.0 | 278.0 | 329.4 | 307.0 | 18.5 | 22.1 | 39.2 | |

| CS2831DF | 319.0 | 283.0 | 34.0 | 278.0 | 329.4 | 307.0 | 18.5 | 18.5 | 39.2 | |

| CS2835DF | 322.5 | 283.5 | 42.0 | 278.0 | 329.4 | 307.0 | 18.5 | 22.1 | 39.2 | |

| CS3020DF | 326.0 | 302.0 | 28.0 | 295.0 | 336.6 | 317.0 | 15.6 | 17.0 | 33.2 | |

| CS3200DF | 352.5 | 320.0 | 40.0 | 312.0 | 365.1 | 343.0 | 20.0 | 21.0 | 42.0 | |

| CS3550DF | 392.0 | 355.0 | 40.0 | 347.0 | 401.7 | 380.0 | 23.0 | 23.0 | 47.6 | |

| CS3790DF | 414.0 | 379.0 | 40.0 | 371.0 | 424.1 | 403.0 | 23.0 | 23.0 | 47.6 | |

| CS4290DF | 458.0 | 429.0 | 42.0 | 421.0 | 477.0 | 447.0 | 18.4 | 22.0 | 38.9 | |

| CS4420DF | 478.0 | 442.0 | 42.0 | 434.0 | 488.7 | 467.4 | 18.4 | 22.0 | 38.9 | |

| CS4421DF | 470.0 | 442.0 | 42.0 | 434.0 | 488.7 | 467.4 | 18.40 | 22.00 | 38.9 | |

| CS4800DF | 515.0 | 480.0 | 44.0 | 475.0 | 530.0 | 502.0 | 22.0 | 24.8 | 48.0 | |

| CS4920DF | 530.0 | 492.0 | 42.0 | 485.0 | 546.0 | 532.0 | 19.9 | 22.0 | 41.7 | |

| CS5000DF | 534.0 | 500.0 | 42.0 | 490.0 | 546.0 | 532.0 | 19.9 | 22.0 | 41.7 | |

| CS5350DF | 580.0 | 535.0 | 45.0 | 525.0 | 600.0 | 581.0 | 24.5 | 28.3 | 53.0 | |

| CS5400DF | 570.0 | 540.0 | 42.0 | 530.0 | 582.8 | 552.7 | 21.4 | 21.4 | 46.6 | |

| CS5700DF | 600.0 | 570.0 | 45.0 | 560 | 615 | 585 | 23.5 | 27.3 | 51 | |

| CS5780DF | 616.0 | 578.0 | 40.0 | 568 | 624 | 600 | 21.5 | 21.5 | 45 | |

| CS6180DF | 670.0 | 618.0 | 50.0 | 608 | 682.5 | 649 | 26 | 30 | 54 | |

| CS6200DF | 664.0 | 620.0 | 50.0 | 610 | 682.5 | 649 | 26 | 30 | 54 | |

| CS6600DF | 692.0 | 660.0 | 46.0 | 650 | 705 | 682 | 24.5 | 26.5 | 52 | |

| CS7490DF | 782.0 | 749.0 | 47.0 | 737 | 812.8 | 779 | 26.1 | 30 | 54 | |

| CS7500DF | 800.0 | 750.0 | 54.0 | 737 | 812.8 | 779 | 26.1 | 27.1 | 58 | |

Long Service Life: These heavy duty seals resist wear and corrosion, ensuring a prolonged service life with minimal maintenance.

Superior Sealing and Effective Contaminant Protection: Our DF metal face seals effectively shield against abrasive substances, moisture, chemicals, oil, and grease.

Alignment Flexibility: Designed to self-center, they accommodate shaft eccentricity and misalignment.

Improved Functionality: Lubrication and cooling between seal faces enable higher rotational speeds.

Fuyote's unique design, where only one metal seal rotates, ensures a maintenance-free and leak-proof seal. This design allows our DF heavy duty seals can offer exceptional durability and can withstand various conditions such as vibrations, misalignment, eccentricity, and assembly wear.

The use of black seal faces reduces rusting and improves O-ring grip, eliminating O-ring sliding. For those preferring white seal faces, Fuyote offers anti-skid stripes to achieve similar effectiveness.

Cross-hatched grooves on the heavy duty seal's contact bands ensure sufficient oil flow and effective heat management, making them suitable for challenging industrial environments beyond the capabilities of traditional rubber oil seals.

All of our DF heavy duty metal face seal products feature precision end grinding surfaces to maintain spherical and angular stability within each batch, preventing premature sealing failures caused by angular discrepancies.

Fuyote designs and produces O-rings tailored to complement their products, known for their high elasticity that minimizes wear and enhances overall durability.

The spherical cant design facilitates alignment of mating boundary lines, offering self-centering capabilities that compensate for shaft eccentricity or misalignment, thereby enhancing seal effectiveness.

DF heavy duty seals utilize two metal sealing rings that interact to create a perpendicular sealing surface. O-rings play a critical role by transferring pressure from the housing to these sealing rings, allowing one ring to rotate with the housing while the other remains stationary. This setup induces relative motion between the two mechanical face seals.

The movement between these seals generates a crucial oil film on the contact surface, essential for effective sealing. During operation, the contacting surfaces form a contact band typically ranging from 0.008 inches (0.2mm) to 0.02 inches (0.5mm) in width. This contact band retains oil lubricant and resists foreign material intrusion. Over time, wear may cause the contact band to shift inward, but the elasticity of the O-ring compensates for this movement, ensuring precise position and stability of the DF heavy duty seals.

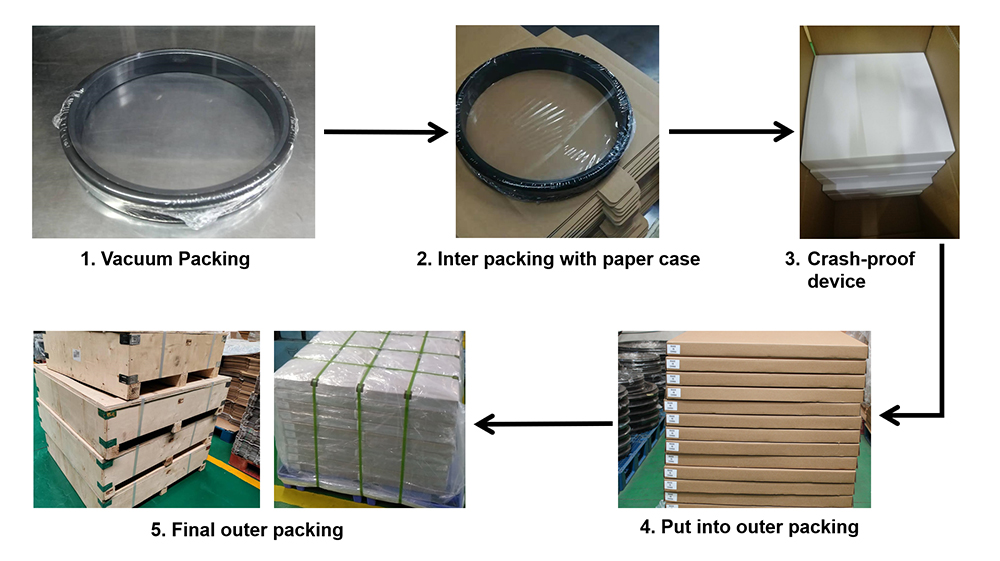

For DF Heavy Duty Seals, Fuyote offers packaging options tailored to quantity, weight, and size.

Choose between sturdy wooden crates or practical paper cases, selected based on transportation requirements. Vacuum packing is utilized to prevent oxidation during transit, ensuring product integrity. To safeguard precision, especially of the contact band, Fuyote employs secure outer structures to prevent crushing.

Fuyote also provides flexible OEM and ODM packaging solutions, including plain or custom packaging featuring logos. For more information on our packaging options, please contact FUYOTE directly.

Fuyote offers comprehensive shipping solutions, including sea and air transportation, tailored to the volume and weight of the goods.

We accommodate customer preferences with FOB and express delivery options, ensuring flexibility to meet specific transportation needs.

Explore our wide range of shipping brands, or contact us for further details.

DF Heavy Duty seals can undergo metamorphic changes when exposed to air for extended periods. Therefore, it's essential to remove the seal package before installation. Due to their fragile nature, handle these DF Heavy Duty seals delicately and install them in a clean, dust-free environment.

For proper installation of O-rings, we strongly advise using dedicated floating seal installation tools. Incorrect installation, such as twisting O-rings, can lead to uneven stress and cause them to dislodge from the metal ring prematurely, resulting in failure.

DF Metal Face Seals, especially the precise contact band, require careful handling to avoid damage. Avoid using sharp tools during assembly and consider wearing gloves.

Store DF Heavy Duty seals in a cool, dark location as O-rings are sensitive to temperature changes. Ensure they are stored flat to prevent deformation due to pressure.

Preventing O-ring twisting is crucial to maintaining even stress distribution and preventing premature failure. Attention to these guidelines is essential for ensuring effective seal performance.

DF heavy duty floating seals should only be used within appropriate pressure and velocity parameters. Careful attention to lubrication practices is crucial. Here are the guidelines:

Recommended temperature range: -40°C to 150°C.

The working linear speed should not exceed a circumferential speed of 10 meters per second.

DF heavy duty seals can typically tolerate a maximum pressure of 0.3 megapascals (MPa).

For effective operation:

Lubricate the seal at the sealing gaps; oil lubrication is preferred over grease.

Maintain the oil level between the midpoint of the axis and two-thirds of the inside diameter of the seal.

Recommended lubricants: SAE 80 and SAE 90 gearbox oils are recommended for lubrication purposes.