Due to the working environment of tunnel boring machines and drilling rigs being in muddy slurry, the working conditions are relatively complex. When the floating seal in the cutterhead is not chosen properly, seal failure can occur, allowing mud and sand to easily enter the interior, causing bearing damage and abnormal wear of the cutterhead, leading to scrapping. Therefore, the self-adjusting capability of the floating seal in response to external pressure is crucial for the cutterhead's lifespan and the machine's operational efficiency.

In floating seals, the important factors that buffer external pressure and stabilize the internal cavity pressure are the spherical design of the floating seal and the cushioning performance of the rubber elasticity.

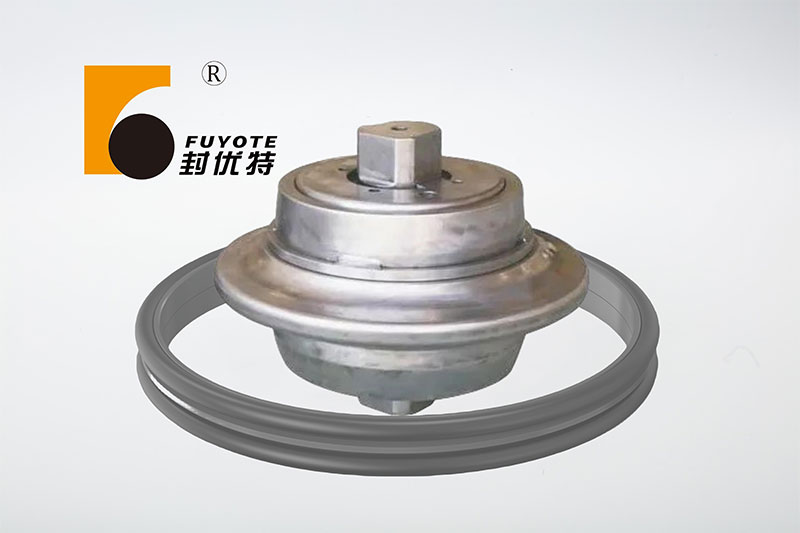

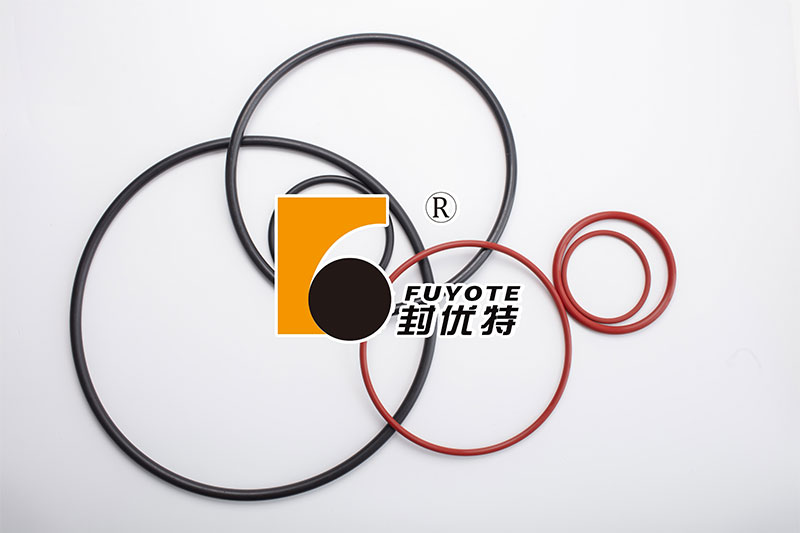

The floating seal consists of two alloy cast iron metal rings and two rubber rings, one dynamic and one static, working in coordination. The o ring is the elastic element, compensating element, and positioning element in the floating seal system. The rubber ring provides a certain amount of compression, causing the two alloy rings to tightly press against each other, forming a friction pair between the two metal rings. The friction pair operates between mud and is subjected to complex forces. When the pressure of the medium around the friction pair changes quantitatively, and the floating seal ring wears and bears a certain tilting force, the elasticity of the o ring in the floating seal is an important factor in maintaining the stable operation of the floating seal.

The elasticity of the o ring in the floating seal of the rolling cutter is crucial. The quality of the rubber's elasticity directly affects the pressure-bearing capacity, sealing performance, and lifespan of the rolling cutter. Additionally, the design of the floating seal is also a critical adjustment factor. For example, the spherical design of the metal seal ring.

Fuyote established in 1992, has been 30 years in china. Focus on floating seals design and manufacture. In the past two decades, large size floating seals are the main products in fuyote’s production line. Diameter from 300mm to 1105mm are the best-selling products in fuyote. In order to guarantee high quality of the products, Fuyote manufactures all components of mechanical face seals in house, from casting metal rings with high chromium molybdenum to manufacturing elastomer components.