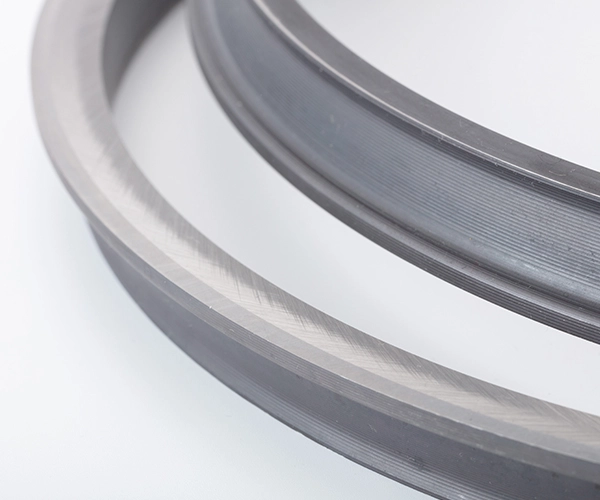

Floating seals consists of metal rings and o-rings, both meterial can do significant impact on sealing. Metal ring’s material decided the Wear and corrosion resistant. And elastomeric o-rings generate a uniform axial face load which acts as static seal at both the inner and outer edges. Additionally, the o-rings transmit turning torque to the static face of the assembly. Therefore o-rings material also need to be careful.

Use casting floating seals instead of forging products. Forging floating seals which are not wear-resistant and relatively brittle cannot be used in the significant parts. The cast iron floating seals have a relatively longer service life and can avoid the difficulty in replacement, as a result, it is more suitable for underground mining machinery, heavy tracks, and conveyor Systems.

Pay attention to metal seal rings material selection and the element content. The content of metal seal rings decide the wear-resistant and the sealing performance directly. For instance, coal mining machinery need used high molybdenum chromium alloy metal seal rings instead of low content.

Select high rubber content of floating seal o-ring. O-rings look the same in appearance, however, the content of o-ring decide the resilience ability and deformation when using in oil conditions.

Choose curve design on sealing face instead of other design. This design has self-centering to compensate for shaft eccentricity or misalignment under the o-ring pressure, which could increase the sealing stability and decrease the assemble difficulty.

Make a comprehensive judgment based on the temperature, speed and working conditions . If you meet any problems of floating seal choosing, please consult FUYOTE.