Floating seals are classified as sealing solutions for rotary equipment. Historically, prior to the widespread adoption of floating seals, skeleton oil seals were the standard at interfaces to safeguard internal bearings and components during machinery operation. However, the transition from skeleton oil seals to floating seals has been observed in numerous machines. What factors have contributed to this shift in preference for sealing technology?

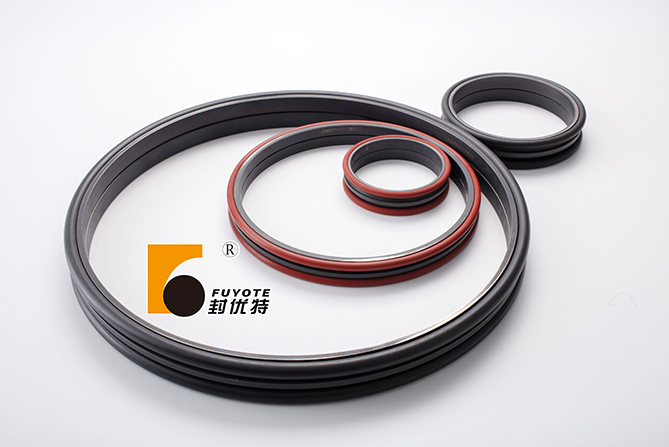

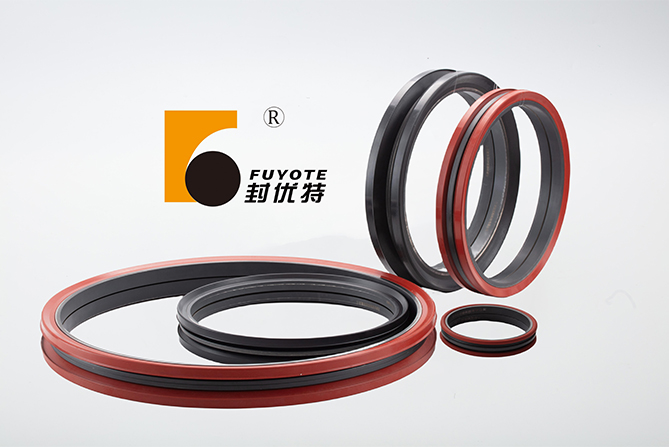

The skeleton oil seal, predominantly comprising rubber, is affixed to the shaft with an adjustment spring, thereby ensuring a state of force equilibrium that facilitates effective oil retention. Its dustproof lip solely performs the function of excluding external contaminants. In conditions where machinery operates at low velocities and the industrial or mining settings are relatively mild, the skeleton oil seal retains a reliable sealing performance. However, in the face of extreme temperatures, high operational speeds, or other severe environments, the seal’s structural design falls short of maintaining the necessary force balance. Under such challenging conditions, the substitution of the skeleton oil seal with a floating seal becomes imperative to secure an optimal sealing outcome. The fuyote’s floating seal, which is installed in a bidirectional manner within the seat cavity, employs a sealing ring and an oil film to accomplish its sealing function.

Fuyote’s floating seals exhibit enhanced durability in severe conditions due to their distinct operational mechanism. Fuyote’s metal seal rings, crafted from a robust molybdenum chromium alloy cast iron, boast wear resistance and extended longevity. These seals incorporate both metallic rings and elastomeric O-rings, with the latter providing not only elastic support within the seal but also buffering against stress during start-up and shutdown periods, thereby bolstering the system’s dependability. Moreover, the installation and upkeep of floating seals are notably straightforward, offering users significant savings in terms of maintenance expenses and time.

In summary, Fuyote’s floating seals, characterized by their outstanding adaptability and reliability, have gained widespread application in the coal mining and construction machinery industries. Notably, in shield machines, coal cutters, tunnel boring machines, and mining carts, floating seals have become a crucial component for maintaining the stable operation of essential equipment. Looking forward, Fuyote is committed to advancing the technology of new materials and to the research and development of manufacturing processes for floating seals. The aim is to further elevate their performance and provide customers with a more dependable sealing system.