In the realm of construction machinery, the choice between skeleton oil seals and floating seals is a prevalent concern, as each type exhibits unique characteristics and is suited for distinct situations. This article will concentrate on the specific conditions under which floating seals should be selected over skeleton oil seals.

The distinction between skeleton oil seals and floating seals can be characterized as follows:

Skeleton oil seal is a type of sealing element that consists of a metal framework enveloped by rubber material. It achieves a frictional seal on a rotating shaft through compression, effectively preventing lubricant leakage. Conversely, floating seal is a mechanism that accomplishes sealing via the buoyancy of an oil film. By generating and sustaining an oil film, it minimizes friction and wear, thereby augmenting the seal’s efficacy.

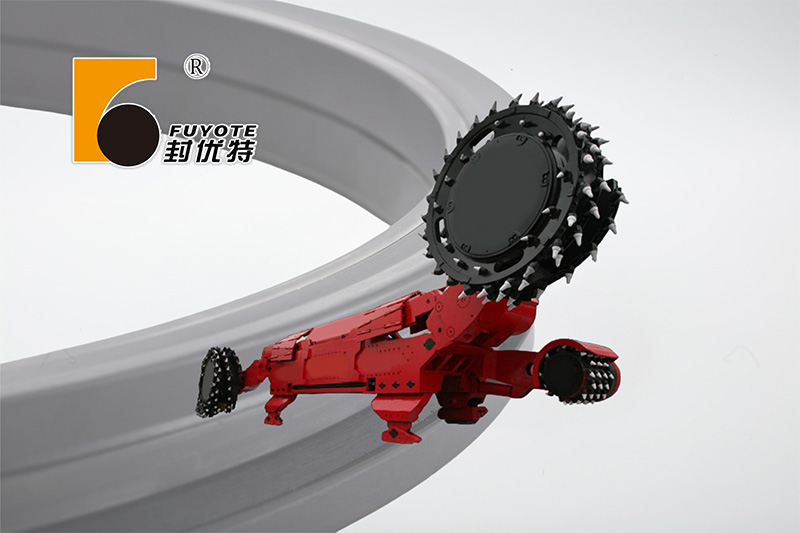

Under specific operational conditions, the use of floating seals can better fulfill sealing requirements. Primarily, floating seals exhibit their distinct benefits in high-speed rotational scenarios. Utilizing the oil film sealing principle, these seals mitigate friction and wear during rapid rotations, thereby prolonging the lifespan of machinery. In contrast, skeleton oil seals frequently succumb to leakage when subjected to high velocities, thereby endangering the safety and reliability of the equipment.

Secondly, under harsh environmental conditions with a high level of external contaminants, floating seals exhibit superior adaptability. The sealing mechanism, which relies on an oil film, effectively prevents water and impurities from penetrating the equipment, thus safeguarding it against contamination or damage. Conversely, due to their structural design, skeleton oil seals are more susceptible to external pollution and can become obstructed by impurities, compromising their sealing efficacy.

In scenarios that require high maintenance and overhaul of equipment, floating seals offer superior advantages. Unlike skeleton oil seals, floating seals can be replaced with greater ease. As floating seals do not require the dismantling of the entire bearing, only the seal itself needs to be replaced. This not only conserves time and labor but is also particularly beneficial in circumstances where maintenance schedules are stringent.

Fuyote established in 1992, has been 30 years in china. Focus on floating seals design and manufacture. In the past two decades, large size floating seals are the main products in fuyote’s production line. Diameter from 300mm to 1105mm are the best-selling products in fuyote. In order to guarantee high quality of the products, Fuyote manufactures all components of mechanical face seals in house, from casting metal rings with high chromium molybdenum to manufacturing elastomer components.