Duo cone seals require precise dimensional coordination between the sealing ring and the O-ring, as well as between the duo cone seal and the application chamber cavity. Firstly, let’s examine the dimensional compatibility between the O-ring and the metal seal ring. If metal seal ring is matched with O-ring of inappropriate size, issues such as too loose installation, sliding, or twisting of the O-ring may occur, preventing the duo cone seal from functioning effectively. Conversely, pairing with O-ring of a smaller inner diameter can lead to insufficient compressive deformation, hindering self-adjustment and increasing the likelihood of premature aging and failure.

The installation precision of duo cone seals is of paramount importance. It is essential to regulate axial and radial runout within the acceptable limits during installation to ensure uniform loading on the duo cone seal, thereby preserving its consistent sealing efficacy. In machine working, the duo cone seal’s floating capacity exhibit sufficient flexibility to compensate for dimensional alterations resulting from shaft misalignments, precluding mechanical seal face failure due to deviations in the shaft’s position.

During the machining process of the bearing housing or end cover, it is essential to ensure that the dimensional accuracy and surface finish meet the installation requirements of the duo cone seal. Moreover, the presence of impurity particles in the operating environment of the duo cone seal should not be overlooked. The protective structure on the surface of the duo cone seal should be capable of effectively preventing impurities from entering the sealed area, to avoid damage to the duo cone seal.

When selecting duo cone seal, attention should also be paid to the seal's dynamic follow ability and adaptability. This requires the duo cone seal to maintain an effective sealing performance at various rotational speeds, and to be capable of adapting to dimensional changes caused by thermal expansion or mechanical vibration. Additionally, the o ring of the duo cone seal should possess a certain level of adjustment ability to compensate for the decrease in preload force due to wear and aging, ensuring that the duo cone seal maintains good sealing performance throughout its entire service life.

Finally, regular inspection and maintenance of the duo cone seals are equally crucial for ensuring the continuous operation of equipment. Proper inspection methods and maintenance strategies can timely detect issues and take corresponding measures to prevent serious equipment damage and production accidents caused by duo cone seal failure.

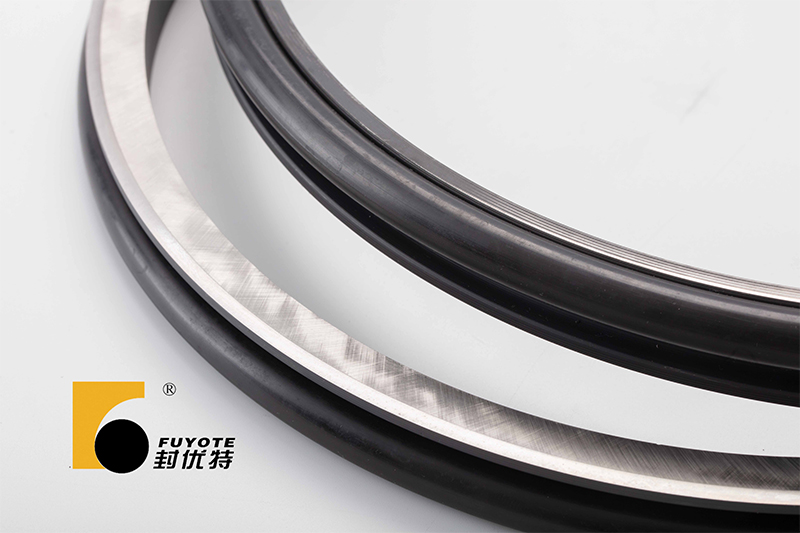

Fuyote established in 1992, has been 30 years in china. Focus on floating seals design and manufacture. In the past two decades, large size floating seals are the main products in fuyote’s production line. Diameter from 300mm to 1105mm are the best-selling products in fuyote. In order to guarantee high quality of the products, Fuyote manufactures all components of mechanical face seals in house, from casting metal rings with high chromium molybdenum to manufacturing elastomer components manufacturing.