Abstract: The floating seal comprises two metal seal rings and two o-rings. The selection of material for the floating seal should be based on the space available in the mechanical equipment and the operating conditions (on the ground, underground, underwater), as well as the rotational speed. Metal seal rings produced by casting exhibit the best performance, with high-content nitrile rubber rings and hydrogenated nitrile rubber rings performing exceptionally well.

In floating seals suitable structure, one half remains stationary while the other half rotates, meeting the requirements that a traditional skeleton oil seal cannot meet. The selection of floating seal design should consider the available cavity space and equipment operating conditions (on the ground, underground, underwater), as well as the rotation speed to determine the appropriate material for the floating seal.

The floating seal comprises two components: metal sealing rings and elastomers.

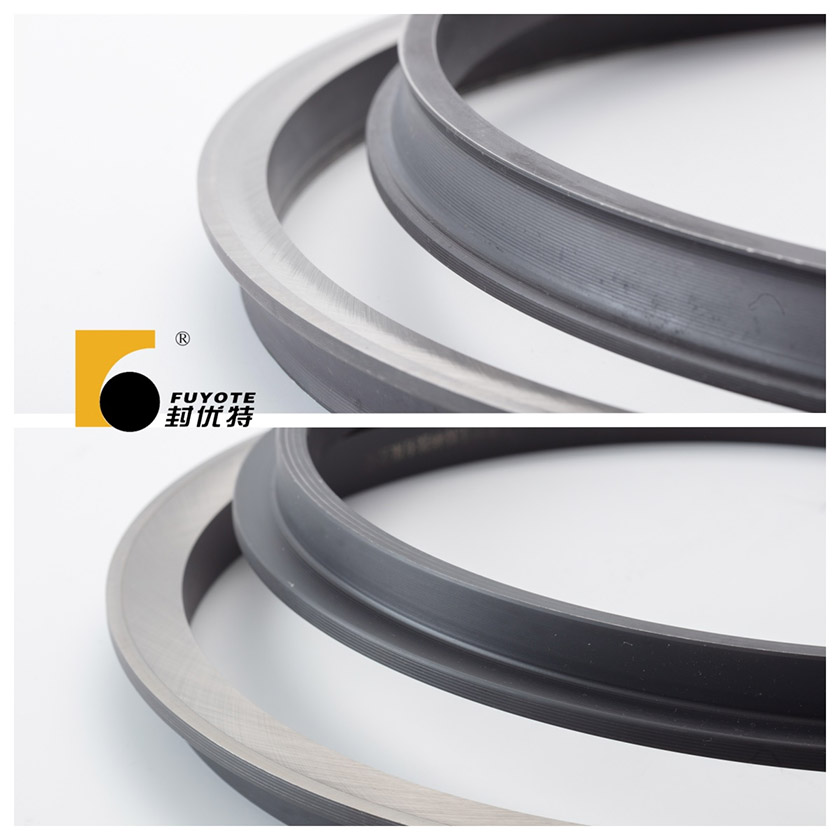

Metal seal rings are generally categorized into two processes: casting and forging. Each process has its own advantages and disadvantages. Among them, cast metal seal rings exhibit the best performance. The upper part of the image depicts the DO type metal seal ring (Duo-cone seals), while the lower part shows the DF type metal seal ring (heavy duty seals).

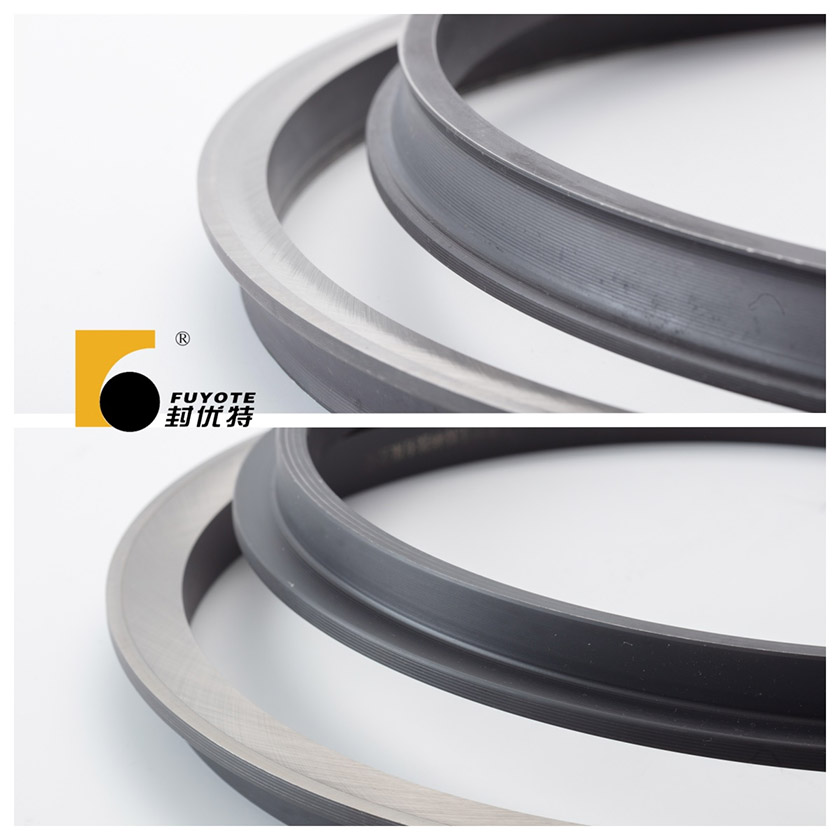

The floating seals are categorized into ordinary NBR (rubber content less than 40%), medium NBR (rubber content between 40% and 60%), and high NBR (rubber content greater than 60%). Due to the direct impact of rubber content on sealing reliability, high NBR usage is significantly superior to ordinary NBR. These three materials constitute 70% of the total market usage of floating seals, with some applications utilizing HNBR and silicone rubber seals extensively in high-temperature equipment, particularly for the exceptional performance of HNBR. The upper part of the image displays the o-ring of DO floating seals (duo cone seals), while the lower part exhibits the rubber of DF floating seals (heavy-duty seals).

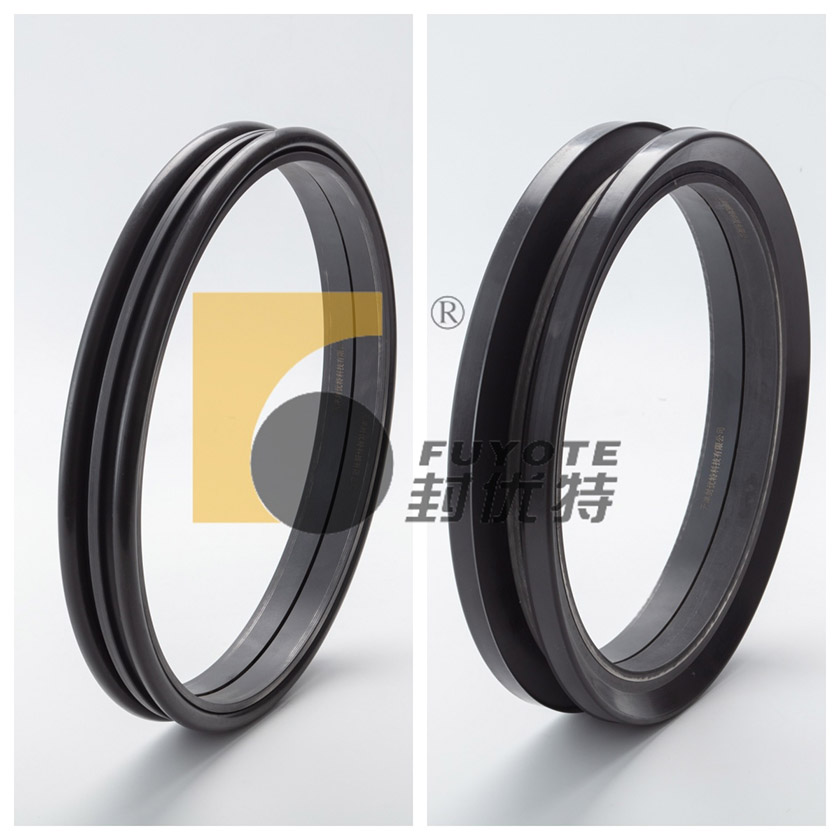

As a crucial sealing component, floating seals, although often overlooked, can lead to significant losses if they fail on the host machine. Therefore, when selecting floating seals, factors such as rotational speed, operating temperature, and operating conditions need to be considered. The left half of the image displays duo cone seals, while the right half showcases heavy-duty seals.