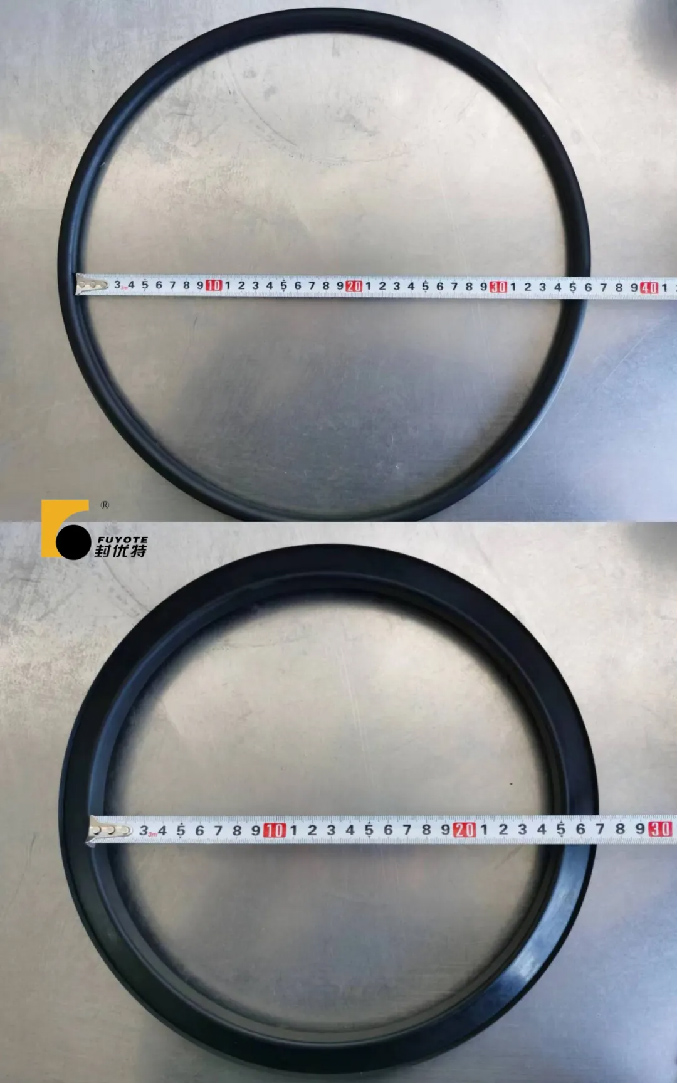

Floating seals should have the dimensions of both the metal seal ring and the rubber ring measured separately. Typically, for the metal seal ring, there are three critical dimensions to be gauged: the outer diameter (OD), the inner diameter (ID), and the height (H). Therefore, precise measurements of the metal seal ring's OD, ID, and H are essential for ensuring the proper functioning of floating seals.

Additionally, accurate dimensions of the rubber ring also play a crucial role in maintaining the floating seal's integrity under varying operating conditions. When measuring an O-ring, it is essential to ascertain two critical dimensions: the O-ring's internal diameter (ID) and its cross-sectional diameter. This procedure is equally applicable for metal face seals’ rubber rings, where these two measurements are pivotal.

By meticulously examining and verifying these key dimensions for both the metal seal rings and rubber components, engineers can optimize the performance and longevity of floating seals in demanding applications.

Fuyote established in 1992, has been 30 years in china. Focus on floating seals design and manufacture. In the past two decades, large size floating seals are the main products in fuyote’s production line. Diameter from 300mm to 1105mm are the best-selling products in fuyote. In order to guarantee high quality of the products, Fuyote manufactures all components of mechanical face seals in house, from casting metal rings with high chromium molybdenum to manufacturing elastomer components manufacturing.