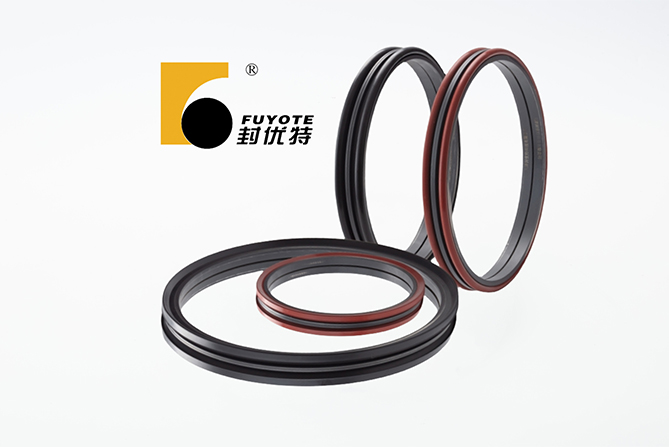

Duo cone seals consist of a combination of metal seal rings and o rings that work together to achieve a balance of forces, thereby maintaining the effectiveness of the seal in retaining oil and preventing dust intrusion. Typically, a duo cone seal is made up of two metal seal rings and two o rings. Each o ring is fitted onto the corresponding metal seal ring and serves to transmit forces between the seating cavity and the metal seal ring. We generally refer to the ring attached to the rotating body as the dynamic ring, while the other end connected to the stationary object is called the static ring. Under the force transmission of the o rings, the dynamic and static rings create an oil film through compressive force. This oil film, under rapid rotation, forms a suction-like effect that blocks external dust and other particles from entering the cavity, while also creating a natural barrier for the oil inside the cavity.

In practical applications, the performance stability of duo cone seals is of paramount importance. The wear resistance of the metal seal ring, the elasticity of the o ring, and the precision of their fit directly impact the lifespan and sealing effectiveness of the duo cone seal. To enhance sealing capabilities, the metal seal ring is typically made from wear-resistant materials such as alloy cast iron, ensuring durability against wear and tear under high-speed rotation and complex operating conditions. Additionally, the surface of the metal seal ring must be precisely machined to maintain a high level of flatness and smoothness. Only then can it form an effective oil film in tight conjunction with the o ring.

For o rings, it is essential to select high-quality synthetic rubber such as nitrile rubber, hydrogenated nitrile rubber, silicone rubber, and fluororubber. Depending on the working environment's temperature, pressure, and medium properties, the appropriate materials and structures should be chosen. The design of the o rings must ensure sufficient pre-compression and resilience to accommodate the centrifugal forces generated by the metal seal rings at high rotational speeds, maintaining an uninterrupted sealing contact. Additionally, o rings should possess excellent resistance to aging and deformation, preventing hardening, cracking, or permanent deformation after prolonged use, thereby retaining their sealing effectiveness.

In the design of duo cone seals, it is also necessary to consider the difference in thermal expansion coefficients between the metal ring and the rubber seal. Through precise calculation and design, it is ensured that the seal assembly can self-adjust in response to temperature changes, maintaining the continuity of the oil film and the sealing performance. Furthermore, by conducting dynamic simulations and experimental validations, the structural parameters and material combinations of the duo cone seals are continuously optimized to achieve a longer service life and higher reliability.

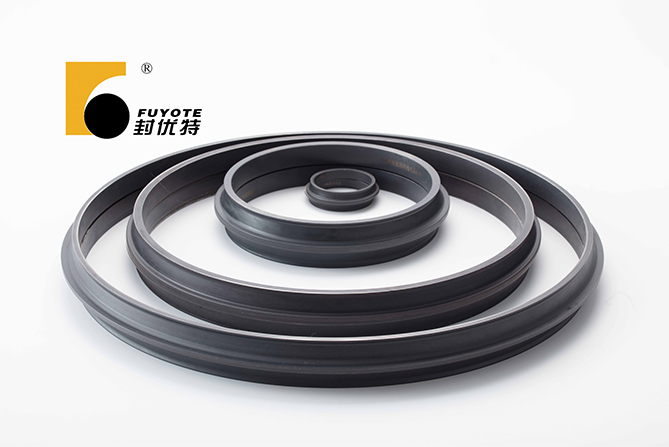

Fuyote established in 1992, has been 30 years in china. Focus on floating seals design and manufacture. In the past two decades, large size floating seals are the main products in fuyote’s production line. Diameter from 300mm to 1105mm are the best-selling products in fuyote. In order to guarantee high quality of the products, Fuyote manufactures all components of mechanical face seals in house, from casting metal rings with high chromium molybdenum to manufacturing elastomer components manufacturing.