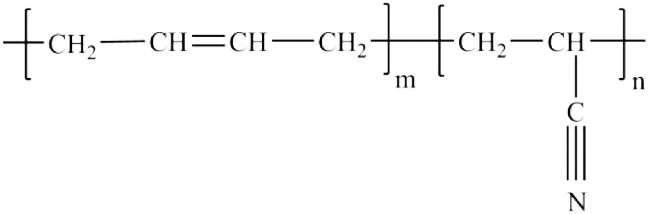

Nitrile rubber is common used in O-ring material, that also known as Buna-N, NBR, and acrylonitrile (ACN) butadiene rubber. NBR which contain a family of unsaturated copolymers of 2-propenenitrile and butadiene monomers is a synthetic rubber. NBR is widely used in a number of applications due to its chemical composition, owing to its several superior features and properties. High amounts of acrylonitrile lead to oil resistance and chemicals. Due to its strong wide temperature operating range, abrasion, and tear resistance, Nitrile rubber is widely chosen for applications across industries, such as off-road equipment, construction machinery, agricultural machinery etc.

The chemical and physical properties of NBR vary in part with the polymer’s composition of nitrile rubber. NBR is the most widely used elastomer in the industry today. It is used in the off-road equipment and construction machinery, since NBR’s ability is to with stand a range of temperatures from -25 to 90°C and other properties.

High abrasion resistance

Good pressure resistance

High tear and tensile strength

Low compression set

Excellent temperature resistance -25 °C to +90 °C

Medium Manufacturing cost

Secondary part application

Less than 1% reaction with oil

NBR's biggest advantage is its resistance to oil and other chemicals. Although its chemical and physical properties depending on the NBR's polymer composition, this particular type of synthetic rubber is unusual in being generally resistant to oil and other chemicals. The more nitrile within the polymer lead to the better resistant to oils and lower flexibility of the material. Otherwise it also has several other desirable properties, such as excellent abrasion resistance, good tear resistance, good rebound, good non-polar solvent resistance, good elongation and excellent compression set resistance, and adequate resilience.

Nitrile rubber is not ideal in applications which require prolonged exposure to ozone, heat , and sunlight. Compared to natural rubber, NBR is not a strong or flexible material. Additionally, it has poor flame resistance, limited high temperature resistance, and moderate operating temperature range.

NItrile rubber (NBR) may still be the right choice for your specific needs, as its advantages still outweigh NBR's disadvantages. When deciding what rubber to choose for your specifications, all of the pros and cons need to be considered. The temperature resistance of NBR makes it ideal for a wide range of applications and working environments, however, chemical compatibility and others properties need also be considered during material choosing.