Material: High alloy cast iron

Seal elastomer(s) used in standard seals: NBR, HNBR, SI

Seal Ring Outer Ø Range (standard parts): 59 to 800 mm

Seal Ring Inner Ø Range (standard parts): 42 to 750 mm

Seal Set Height Range (standard parts): 20 to 54 mm

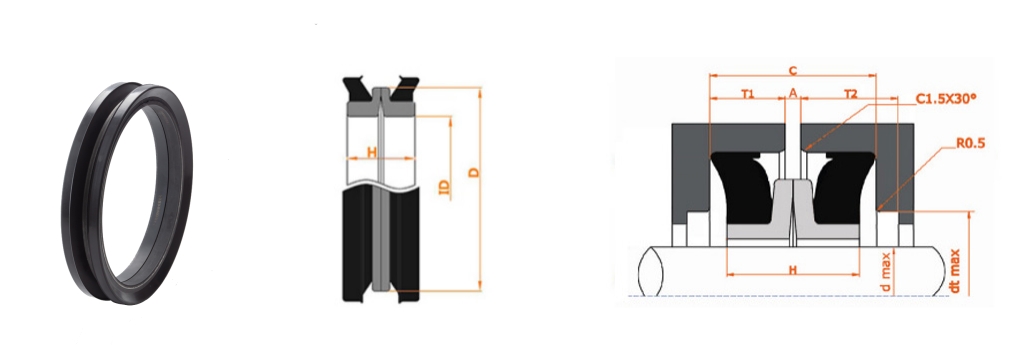

To create a contact sealing face perpendicular to the axis, two metal seal rings engage with one another. One metal seal ring can rotate with the housing thanks to o-rings that transfer pressure from the housing to it, while the other one is kept in place. This places two mechanical face seals in a state of relative motion.

An oil film is produced on the surface of the contact band by two substantially moving face seals. The sealing process relies on this oil film. When rotating, the mating faces create a contact band that is between 0.2mm (0.008") and 0.5mm (0.02") wide, which helps to keep the oil lubricant in place and resist extraneous objects. The contact band will inwardly shift while you wear it. But the o-ring releases elastic compensation, maintaining the precise position of the mechanical face seals to maintain the seal.

Exceptional sealing capacity against outside contaminants such abrasive media, moisture, chemicals, oil, and grease.

Wear and corrosion resistant, long service life, maintenance free.

Self-centering to account for shaft eccentricity or misalignment.

Oil lubricates and cools the seal faces, enabling faster spinning speeds.

The Fuyote design, in which just one metallic seal rotates, produces a leak-proof seal, requires no maintenance, offers an exceptionally long service life, and accounts for vibrations, misalignment, eccentricity, assembly wear, and other circumstances. The advantages of the FUYOTE product are displayed below.

Black seal faces prevent rusting and improve o-ring grip, which prevents o-ring sliding. Fuyote provides anti-skid stripes to customers who need white seal faces in order to get the same result.

Cross-hatched grooves on the seal contact bands guarantee adequate oil flow and heat control, allowing the seals to function under the most demanding industrial situations. The issue that a rubber oil seal cannot solve is also resolved at the same time.

A specific procedure is used to create each product's end grinding surface. It prevents early sealing failure owing to angular mismatch between goods in the same batch and ensures spherical angular stability of those products.

FUYOTE manufactures and designs o-rings to go with its own goods. High elasticity makes items robust by increasing wear resistance.

The two meshing boundary lines coincide, which is advantageous for spherical cant design. Allow self-centering to correct any eccentricity or misalignment in the shaft.

When exposed to air for an extended period of time, mechanical face seals change. Before installation, only take out the seal packing. It is simple to damage mechanical face seals. Install in a clean environment and handle cautiously.

To ensure accurate o-ring installation, we advise the use of installation tools. Twist on o-rings could cause unequal stress and slip down from the metal ring if they are put incorrectly. ultimately result in early failure.

Especially the contact band, mechanical face seals are very precise products. When assembling, avoid using sharp objects, and put on gloves.

Because the O-ring is temperature-sensitive, the floating seal must be stored in a dark, cool environment. Do not crush storing and lay flat.

O-ring twisting may result in unequal tension, creep down from the metal ring, and ultimately early failure.

In the wrong pressure and velocity conditions, a floating seal cannot be used. In addition, care must be used when using lubricants.

Optimum temperature range: -40 to 150 degrees Celsius

Working liner speed: capable of withstanding a circumferential speed of up to 10 m/sec.

Typically, floating seals are limited to 0.3 MPa of pressure.

It is crucial to lubricate the seal at the sealing gaps; oil lubrication is preferred over grease lubrication.

The oil level must be between the axis' midpoint and the seal's inner diameter, or about two-thirds of its diameter. It is advised to use SAE 80 and SAE 90 gearbox oils.

| Drawing No. | Seal Set | Shaft (Max) d | Housing Bore | |||||||

| PN# | A= | D | ID | H | Bore depth de | Recommended shoulder dia dt | Bore depth T1 | T2 | C | |

| CS0420DF | 59.0 | 42.0 | 20.0 | 39.0 | 65.0 | 53.0 | 10.0 | 10.5 | 23.0 | |

| CS0470DF | 62.0 | 47.0 | 20.0 | 44.0 | 70.0 | 58.0 | 11.5 | 11.5 | 23.0 | |

| CS0450DF | 65.0 | 45.0 | 22.0 | 42.0 | 70.1 | 58.0 | 11.5 | 12.1 | 24.7 | |

| CS0505DF | 65.0 | 50.5 | 19.0 | 46.5 | 76.2 | 63.0 | 10.5 | 11.0 | 23.0 | |

| CS0540DF | 73.0 | 54.0 | 22.0 | 50.0 | 80.0 | 67.0 | 11.5 | 12.0 | 26.0 | |

| CS0585DF | 73.0 | 58.5 | 19.0 | 54.0 | 82.6 | 65.0 | 10.0 | 11.0 | 23.0 | |

| CS0586DF | 80.0 | 58.6 | 19.6 | 54.0 | 84.0 | 71.0 | 9.0 | 9.5 | 21.0 | |

| CS0600DF | 80.0 | 60.0 | 24.0 | 56.0 | 85.0 | 70.0 | 10.5 | 10.5 | 28.0 | |

| CS0635DF | 81.0 | 63.5 | 19.0 | 59.5 | 87.8 | 71.0 | 9.0 | 9.5 | 21.0 | |

| CS0670DF | 86.2 | 67.0 | 20.0 | 64.0 | 95.5 | 82.0 | 10.0 | 11.0 | 23.0 | |

| CS0671DF | 91.7 | 67.0 | 20.0 | 64.0 | 95.5 | 82.0 | 10.0 | 11.0 | 23.0 | |

| CS0740DF | 92.8 | 73.8 | 20.0 | 70.0 | 102.2 | 88.0 | 10.0 | 11.0 | 23.0 | |

| CS0741DF | 99.0 | 74.0 | 20.0 | 70.0 | 102.2 | 88.0 | 10.0 | 11.0 | 23.0 | |

| CS0760DF | 90.0 | 76.0 | 17.0 | 73.0 | 95.0 | 83.0 | 8.0 | 9.5 | 18.0 | |

| CS0770DF | 97.0 | 77.0 | 25.0 | 74.0 | 105.0 | 87.0 | 12.5 | 13.5 | 29.0 | |

| CS0820DF | 101.5 | 82.0 | 20.0 | 78.0 | 110.2 | 96.0 | 10.0 | 11.0 | 23.0 | |

| CS0825DF | 100.0 | 82.5 | 22.0 | 78.0 | 114.3 | 97.0 | 11.0 | 12.0 | 25.5 | |

| CS0875DF | 111.5 | 87.5 | 19.0 | 85.0 | 115.8 | 102.0 | 10.0 | 11.0 | 23.0 | |

| CS0880DF | 104.0 | 88.0 | 19.0 | 85.5 | 113.0 | 98.0 | 8.0 | 9.5 | 20.0 | |

| CS0920DF | 113.0 | 92.0 | 24.0 | 88.0 | 125.8 | 109.0 | 12.5 | 13.0 | 28.0 | |

| CS0940DF | 115.0 | 94.0 | 24.0 | 90.0 | 125.8 | 109.0 | 12.5 | 13.0 | 28.0 | |

| CS0941DF | 120.0 | 94.0 | 24.0 | 90.0 | 125.8 | 109.0 | 12.5 | 13.0 | 28.0 | |

| CS0990DF | 123.0 | 99.0 | 19.0 | 95.0 | 127.3 | 113.0 | 10.0 | 11.0 | 23.0 | |

| CS0991DF | 120.0 | 99.0 | 17.5 | 95.0 | 124.0 | 110.0 | 8.5 | 9.5 | 20.0 | |

| CS1040DF | 132.0 | 104.0 | 27.0 | 100.0 | 141.2 | 121.0 | 15.0 | 16.0 | 32.2 | |

| CS1050DF | 124.0 | 105.0 | 24.0 | 100.0 | 135.0 | 114.0 | 12.0 | 13.0 | 28.0 | |

| CS1140DF | 133.2 | 114.0 | 26.0 | 110.0 | 148.0 | 130.0 | 12.0 | 13.0 | 28.0 | |

| CS1141DF | 138.0 | 114.0 | 26.0 | 110.0 | 148.0 | 126.0 | 12.0 | 13.0 | 28.0 | |

| CS1150DF | 141.0 | 115.0 | 28.0 | 112.0 | 152.4 | 131.4 | 15.3 | 15.3 | 33.6 | |

| CS1240DF | 144.0 | 124.0 | 32.0 | 120.0 | 162.5 | 142.0 | 18.3 | 20.0 | 39.6 | |

| CS1330DF | 156.0 | 133.0 | 28.0 | 128.0 | 171.5 | 151.0 | 15.3 | 15.3 | 32.6 | |

| CS1340DF | 155.6 | 134.0 | 22.0 | 130.0 | 162.6 | 152.0 | 10.7 | 13.1 | 22.8 | |

| CS1425DF | 161.0 | 142.5 | 24.0 | 138.0 | 173.0 | 139.7 | 11.1 | 11.1 | 27.7 | |

| CS1430DF | 165.0 | 143.0 | 28.0 | 139.0 | 177.5 | 168.0 | 15.8 | 16.8 | 33.6 | |

| CS1431DF | 166.0 | 143.0 | 28.0 | 139.7 | 174.0 | 158.8 | 15.5 | 15.5 | 33.0 | |

| CS1480DF | 172.0 | 148.0 | 29.0 | 144.0 | 184.5 | 164.7 | 16.5 | 16.5 | 35.0 | |

| CS1485DF | 167.9 | 148.5 | 28.0 | 143.0 | 184.1 | 164.0 | 16.5 | 18.0 | 35.0 | |

| CS1481DF | 168.0 | 148.5 | 32.4 | 143.0 | 188.9 | 172.0 | 16.5 | 16.5 | 36.0 | |

| CS1500DF | 175.0 | 150.0 | 30.0 | 145.0 | 190.0 | 170.0 | 16.5 | 18.0 | 35.0 | |

| CS1501DF | 177.0 | 150.0 | 32.0 | 145.0 | 184.1 | 164.0 | 16.5 | 18.0 | 35.0 | |

| CS1520DF | 178.0 | 152.0 | 32.0 | 149.0 | 192.0 | 172.0 | 14.0 | 16.5 | 31.0 | |

| CS1540DF | 180.0 | 154.0 | 36.0 | 149.0 | 194.0 | 174.0 | 18.4 | 18.4 | 38.5 | |

| CS1541DF | 180.4 | 154.0 | 30.0 | 149.0 | 190.0 | 170.0 | 16.0 | 18.0 | 35.0 | |

| CS1580DF | 180.0 | 158.0 | 18.0 | 153.0 | 190.0 | 174.0 | 8.0 | 10.0 | 22.0 | |

| CS1600DF | 180.0 | 160.0 | 36.0 | 155.0 | 194.0 | 174.0 | 18.4 | 18.4 | 38.5 | |

| CS1630DF | 184.0 | 163.0 | 30.0 | 158.0 | 190.5 | 175.0 | 15.0 | 15.0 | 31.8 | |

| CS1690DF | 195.0 | 169.0 | 33.0 | 164.0 | 206.2 | 191.5 | 15.1 | 18.4 | 32.2 | |

| CS1740DF | 194.0 | 174.0 | 23.0 | 170.0 | 204.7 | 190.5 | 10.7 | 13.1 | 22.8 | |

| CS1780DF | 207.0 | 178.0 | 29.0 | 174.0 | 218.9 | 197.0 | 16.5 | 16.5 | 35.0 | |

| CS1920DF | 218.0 | 192.0 | 32.0 | 187.0 | 231.0 | 206.0 | 15.2 | 17.0 | 32.4 | |

| CS1930DF | 214.3 | 193.0 | 32.0 | 188.0 | 238.7 | 215.0 | 20.1 | 20.1 | 42.2 | |

| CS1931DF | 223.0 | 193.0 | 32.0 | 188.0 | 238.7 | 215.0 | 20.1 | 20.1 | 42.2 | |

| CS1980DF | 224.0 | 198.0 | 35.0 | 195.0 | 245.0 | 223.0 | 17.0 | 17.0 | 40.0 | |

| CS1981DF | 220.0 | 198.0 | 18.0 | 195.0 | 228.6 | 212.0 | 10.5 | 12.0 | 23.0 | |

| CS2030DF | 229.5 | 203.0 | 38.0 | 198.0 | 254.0 | 235.0 | 21.2 | 23.0 | 44.5 | |

| CS2060DF | 237.5 | 206.0 | 38.0 | 202.0 | 254.0 | 235.0 | 21.2 | 23.0 | 44.5 | |

| CS2135DF | 238.0 | 213.5 | 28.0 | 209.0 | 254.0 | 240.0 | 13.7 | 15.2 | 32.0 | |

| CS2140DF | 242.0 | 215.0 | 38.0 | 210.0 | 255.5 | 235.0 | 18.9 | 21.2 | 39.6 | |

| CS2150DF | 249.0 | 215.0 | 38.0 | 210.0 | 255.5 | 235.0 | 18.90 | 21.20 | 39.6 | |

| CS2220DF | 244.6 | 222.0 | 22.0 | 217.0 | 254.0 | 240.0 | 10.5 | 10.5 | 23.0 | |

| CS2250DF | 246.0 | 225.0 | 40.0 | 221.0 | 277.1 | 247.0 | 23.7 | 23.7 | 49.0 | |

| CS2251DF | 246.0 | 225.0 | 36.0 | 221.0 | 266.8 | 247.0 | 18.2 | 18.2 | 38.1 | |

| CS2260DF | 256.0 | 226.0 | 40.0 | 220.0 | 277.1 | 247.0 | 23.7 | 23.7 | 49.0 | |

| CS2280DF | 260.5 | 228.0 | 40.0 | 221.0 | 277.1 | 247.5 | 23.7 | 23.7 | 49.0 | |

| CS2330DF | 259.0 | 233.0 | 35.0 | 225.0 | 280.0 | 250.0 | 17.0 | 18.0 | 40.0 | |

| CS2360DF | 265.0 | 236.0 | 30.0 | 231.0 | 273.1 | 230.0 | 15.6 | 17.0 | 34.2 | |

| CS2380DF | 261.9 | 238.0 | 22.0 | 233.0 | 269.9 | 255.0 | 10.7 | 10.7 | 22.9 | |

| CS2390DF | 264.0 | 239.0 | 36.0 | 234.0 | 279.4 | 261.9 | 17.5 | 20.0 | 36.5 | |

| CS2410DF | 261.3 | 241.0 | 22.0 | 236.0 | 269.9 | 255.0 | 10.6 | 10.6 | 22.2 | |

| CS2415DF | 273.5 | 241.5 | 36.0 | 236.0 | 279.4 | 260.6 | 17.5 | 20.0 | 36.5 | |

| CS2416DF | 273.5 | 241.6 | 36.0 | 236.0 | 295.3 | 273.0 | 21.3 | 21.3 | 44.6 | |

| CS2470DF | 270.5 | 247.0 | 41.0 | 243.0 | 301.2 | 272.0 | 23.5 | 23.5 | 49.5 | |

| CS2485DF | 269.1 | 248.5 | 28.0 | 243.0 | 279.4 | 260.0 | 12.7 | 12.7 | 28.9 | |

| CS2520DF | 282.0 | 252.0 | 38.0 | 248.0 | 295.2 | 272.0 | 20.7 | 23.0 | 44.5 | |

| CS2580DF | 286.0 | 258.0 | 28.0 | 253.0 | 292.1 | 276.0 | 15.6 | 17.0 | 33.2 | |

| CS2750DF | 303.0 | 275.0 | 36.0 | 270.0 | 309.4 | 290.0 | 17.5 | 20.0 | 37.0 | |

| CS2830DF | 305.0 | 283.0 | 42.0 | 278.0 | 329.4 | 307.0 | 18.5 | 22.1 | 39.2 | |

| CS2831DF | 319.0 | 283.0 | 34.0 | 278.0 | 329.4 | 307.0 | 18.5 | 18.5 | 39.2 | |

| CS2835DF | 322.5 | 283.5 | 42.0 | 278.0 | 329.4 | 307.0 | 18.5 | 22.1 | 39.2 | |

| CS3020DF | 326.0 | 302.0 | 28.0 | 295.0 | 336.6 | 317.0 | 15.6 | 17.0 | 33.2 | |

| CS3200DF | 352.5 | 320.0 | 40.0 | 312.0 | 365.1 | 343.0 | 20.0 | 21.0 | 42.0 | |

| CS3550DF | 392.0 | 355.0 | 40.0 | 347.0 | 401.7 | 380.0 | 23.0 | 23.0 | 47.6 | |

| CS3790DF | 414.0 | 379.0 | 40.0 | 371.0 | 424.1 | 403.0 | 23.0 | 23.0 | 47.6 | |

| CS4290DF | 458.0 | 429.0 | 42.0 | 421.0 | 477.0 | 447.0 | 18.4 | 22.0 | 38.9 | |

| CS4420DF | 478.0 | 442.0 | 42.0 | 434.0 | 488.7 | 467.4 | 18.4 | 22.0 | 38.9 | |

| CS4421DF | 470.0 | 442.0 | 42.0 | 434.0 | 488.7 | 467.4 | 18.40 | 22.00 | 38.9 | |

| CS4800DF | 515.0 | 480.0 | 44.0 | 475.0 | 530.0 | 502.0 | 22.0 | 24.8 | 48.0 | |

| CS4920DF | 530.0 | 492.0 | 42.0 | 485.0 | 546.0 | 532.0 | 19.9 | 22.0 | 41.7 | |

| CS5000DF | 534.0 | 500.0 | 42.0 | 490.0 | 546.0 | 532.0 | 19.9 | 22.0 | 41.7 | |

| CS5350DF | 580.0 | 535.0 | 45.0 | 525.0 | 600.0 | 581.0 | 24.5 | 28.3 | 53.0 | |

| CS5400DF | 570.0 | 540.0 | 42.0 | 530.0 | 582.8 | 552.7 | 21.4 | 21.4 | 46.6 | |

| CS5700DF | 600.0 | 570.0 | 45.0 | 560 | 615 | 585 | 23.5 | 27.3 | 51 | |

| CS5780DF | 616.0 | 578.0 | 40.0 | 568 | 624 | 600 | 21.5 | 21.5 | 45 | |

| CS6180DF | 670.0 | 618.0 | 50.0 | 608 | 682.5 | 649 | 26 | 30 | 54 | |

| CS6200DF | 664.0 | 620.0 | 50.0 | 610 | 682.5 | 649 | 26 | 30 | 54 | |

| CS6600DF | 692.0 | 660.0 | 46.0 | 650 | 705 | 682 | 24.5 | 26.5 | 52 | |

| CS7490DF | 782.0 | 749.0 | 47.0 | 737 | 812.8 | 779 | 26.1 | 30 | 54 | |

| CS7500DF | 800.0 | 750.0 | 54.0 | 737 | 812.8 | 779 | 26.1 | 27.1 | 58 | |