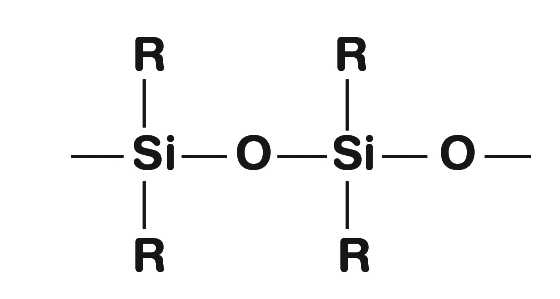

Silicone rubber is identified as a synthetic elastomer as it is a polymer which displays viscosity and elasticity. Silicone is made of carbon, hydrogen, oxygen and silicon. The production process to make silicon is complex and involves many stages, such as the silicone-making process involves extracting silicon from silica which is derived from sand and passing it through hydrocarbons.As a result, silicone rubber has premium price compared to other rubbers. Silicone rubber is a combination of an inorganic Si-O backbone which could give silicone its high temperature resistance and flexibility over a wide range of temperatures with organic functional groups attached. Silicone rubber is a highly-resistant and durable elastomer. Stiff gum which can be crosslinked at elevated temperature is formed by mixing with reinforcing fillers and the silicone polymer. The silicone becomes a solid and elastomeric material once crosslinked.

Silicone rubber is a synthetic rubber elastomer which is frequently used for many applications. Silicon Rubber is a human-made elastomer. It has the properties of both plastic and rubber. It built on a base of silicon, oxygen, and groups of organic molecules, that lend silicone rubber its flexibility. Silicone rubber is a durable and highly-resistant elastomer. It is a high-performance elastomer characterized by an unusual combination of properties such as temperature resistance, durability, and non-toxicity, among many other properties.

Silicone rubber has relatively long polymer chains & high molecular weight, and also its molecular structure consists of siloxane bonds which contributes to its low thermal conductivity. This characters make it an excellent heat resistant and thermally stable material. However silicone rubber advantages and disadvantages come down to its properties. Silicone rubber can be prone to tearing under certain conditions due to the weak nature of the chains. As a result silicone rubber often reinforced with fumed silica to make it more tear resistant. Silicone rubbers can withstand temperatures (-50°C to 200°C) depending on the duration of exposure. When exposed to rain, wind, and UV rays for long periods, silicone rubber results in virtually no change in physical properties. Compared to organic rubber, silicone rubber has a Si-O bond in its structure, as a result, it has better heat resistance, chemical stability, electrical insulation, abrasion resistance, weatherability, ozone resistance, and compress ability. However, the drawbacks of silicone rubber can also be found, such as it is not oil resistant for long periods of time and can swell after long periods of contact with oil. silicone rubber can get stiffer at higher temperatures and it is one of the most expensive types of rubber.

Wide service temperature range: from -50°C to 200°C

Excellent resistance to attack by oxygen, ozone and sunlight

Readily resistant to electromagnetic and particle radiation (UV, alpha, beta and gamma rays)

Low toxicity

Low chemical reactivity

Excellent mechanical properties (high tear strength, high elongation)

Excellent resistance to extreme temperatures

Remarkable heat resistance and flame retardant

Great retention of flexibility and mechanical integrity

Excellent corrosion resistance

Great tear strength and chemical stability

Low pressure resistant

Medium tear resistant

Medium manufacturing cost

Larger than 2% reaction with oil

The production process and material composition of silicone rubber gives it a great amount of flexibility and able to withstand extreme fluctuations in temperature from -50°C to 200°C. Due to its chemically stable and weather resistant silicone rubber also has excellent environmental resistance from wind, Ozone, UV and general weathering stresses. Except its flexible, durable and chemically inert, silicone rubber not only oil resistant, but also doesn’t react with most substances which make it an ideal use in harsh chemicals expose, such as mining and construction machinery. Moreover silicone rubber’s high temperature resistance makes silicone the only mold rubber suitable for casting alloy metal of floating seal.

Silicone rubber has poor oil resistance, and can lose and swell its shape and form after extended exposure to oil. Moreover It need to add other ingredients to alter the chemical makeup to enhance its tear resistance. Silicone rubber is one of the more expensive elastomers due to Its high quality. All the properties need to be considered when deciding on which rubber to choose for your application.

The key difference between rubber and silicone rubber is the backbone of silicone contains silicon and oxygen, while rubber forms contain carbon-carbon bonds. Different rubber occurs different reaction to various environments, due to different atomic structures between rubber and silicone rubber. Normal rubber will withstand temperatures of up to around 90°C before it starts to melt and degrade. However silicone rubber could withstand temperatures of up to 200°C. As a result, silicone also used in high temperature applications and offers a better level of flame resistance than rubber. Silicone rubber also has a better weather resistance, chemical resistance, and UV resistance than rubber, which could be used outdoors and stop them from break down extremely quickly. Furthermore, rubbers have better tensile and tear properties at high temperatures while these properties are excellent in silicone rubbers at the same conditions. However in normal temperature, natural rubber exhibits much higher tensile strength, tear strength, and abrasion resistance than silicone. Compared to rubber, silicone rubber has relatively low abrasion resistance and tend to used in applications where a part will be subjected to abrasion and wear. Silicone has excellent resistance to weathering and UV and is often found in outdoor applications, however rubber is not suited to Extremely applications.